solution

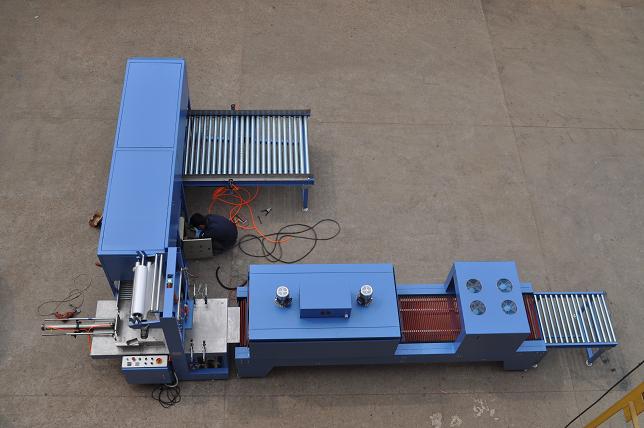

Cement foam board packaging line

add time :2012-08-28 quote link:http://www.shrinkmachine.cn/new_show294.html

Full automatic cement packing line is Qingdao Ausense packaging equipment co., LTD., one of self-developed patent product, this system has the following features:

A, cement foam insulation board packaging is divided into seven system composition:

1. The feeder system

2. Code sorting system

3. The caching system

4. The sealing and cutting sack packaging system

5. Heat shrinkable packaging machine system

6. The cooling system

7. Dust removal system

Second, the structure characteristics of cement foam board packaging line

1, energy saving

This system adopts the Ausense original closed circulate in eddy current heating and heat preservation system, not only improve the heating efficiency, but also reduces the heat loss, the high efficiency and energy saving effect

2, environmental protection

First of all, Ausense environmental protection material as packaging company with PE membrane cement foam insulation board of packaging materials.Second, cement foamed board dust big, easy to fracture, Ausense company adopts PE plastic film will be foamed cement all the corners, and horizontal plane all packaging, effectively improved, the product after delivery and use of the environment.Finally, in the process of cement foam insulation board packaging, not only made a effective protection, the friction parts of the equipment at the same time joined the dust removal system, reduces the equipment surrounding dust get.

3, automatic, unmanned operation

The system input, automatic packaging finished product output automatically, without human intervention.

4, the flexible design

This system's largest packaging specifications for L (600-300) * * H300MM W500;Basic covers all the size of the cement foamed board on the market.In this range, can according to the size of the product, adjust the packing size, various specifications can make 1 set of equipment packaging.

Three, cement foamed board unmanned working principle of packing line

This system adopts the PE film sleeve type automatic sack of cement foam board of packaging.

Biggest packaging specifications for: H300 L600 * * W500mm

The process is as follows:

When cement foamed board from cutting device to the power line roller, cement foam plate uniform operation to automatic pendulum qi sorting device, the detection of cement foam board and the sensor sensing signal, at the ends of the cylinder, when the sensor delay work stopped, cylinder, falling exercise of cement foam plate on the next trip power delivery, when the cement foamed board to power roller line edge, the detection of cement foam board conveyor in place of the sensor sensing signal, and then the chain conveyer start running, cement foamed board will be under the thrust of the chain push board from the power roller conveyor to the unpowered roller conveyor transition, when pushing plate pushing cement foam board to FengQieJi mesa, sealing and cutting machine lateral induction sensor sensing signal, the arrival of cement foam board for sealing and cutting action, sealing and cutting after delivery directly to the inner loop heat shrinkable machine, shrink and packaging process.And then push the board will continue to push forward the cement foam board, FengQieJi circular movement, until push board run to sensors without cement foam board, pushing plate movements for the next cycle.

Four, involving the product:

Automatic conveyor, code machine, crib, sealing and cutting machine, heat shrink packaging machine, etc

Qingdao Ausense packaging equipment co., LTD., facing the whole country invites agents and partners.